We brew sake in Okayama, Japan since 1885

Tanaka Sake Brewery Mimasaka local sake『Musashinosato』Jummai-shu『chu-ko』

1655, Furumachi, Mimasaka, Okayama, Japan 7070412

TEL:0868-78-2059/FAX:0868-78-3378

Open: 9:00 am~Close: 19:00 pm Closed every Wednesday

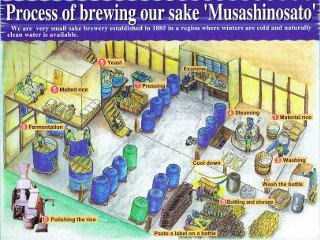

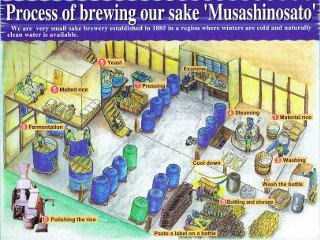

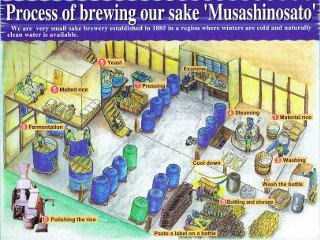

Process of Brewing Sake

We brew sake only in winter (December - March).

We brew sake only in winter (December - March).

There are big 5 steps to brew sake.

1.Steam up rice.

2.Grow "KOUJI" with steam-up rice and kouji bacteria.

3.Grow "MOTO" with steam-up rice and "KOUJI" and yeast and water.

4.To a tank, with steam-up rice and "KOUJI" and "MOTO" and water.

5.After 3 to 4 weeks, press it. Sake is born.

1,Material rice

Most of the rice we use comes from the local area.

Most of the rice we use comes from the local area.

For DAIGINJO and JUNMAI DAIGINJO we use special rice from a famous region.

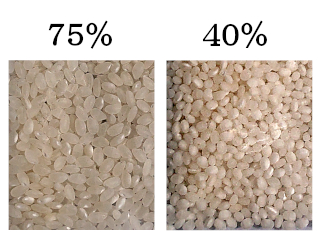

2,Polishing rice

We eat about 0-8%of the outer bran removed after polishing.

We eat about 0-8%of the outer bran removed after polishing.

For brewing sake the rice used normally has 25-40% removed, and for GINJO about 50-60% is removed for a more pure taste.

3,Washing rice

In brewing GINJO we don't use any machines. For washing rice,it's done only by hand with a large amount of water.

In brewing GINJO we don't use any machines. For washing rice,it's done only by hand with a large amount of water.

4,Steaming rice

In a large iron pot, water is boiled and the rice is steamed, Then the rice is removed using a large shovel.

In a large iron pot, water is boiled and the rice is steamed, Then the rice is removed using a large shovel.

This work is hard because of the heat.

After steaming, the temperature of the rice is cool down for yeast.

5,The yeast and the malted rice

Starch from the rice is used to from a glucose substance which becomes the malted rice.

Starch from the rice is used to from a glucose substance which becomes the malted rice.

This malted rice is fermented to make yeast, which is the basis of sake.

It is important to grow good yeast to brew good sake.

6,Fermentation

The steamed rice, malted rice and yeast along with water are all placed in a large tank where fermentation occurs.

The steamed rice, malted rice and yeast along with water are all placed in a large tank where fermentation occurs.

Therefore a temperature of between 10-15C is maintained.

Microbes love fresh air, so the mixture is stirred with a large paddle to allow fresh air in.

The temperature is constantly adjusted the appropriate level.

7,Pressing

After 3-5weeks into the process, the rice mixture is stuffed into special bags attached to a machine which squeezes out sake leaving behind remaining solids called 'sake cake'

This process uses 120-150 bags,and removing the sale from then is difficult. (Our sake cake are delicious because of traditional press machine.)

After 3-5weeks into the process, the rice mixture is stuffed into special bags attached to a machine which squeezes out sake leaving behind remaining solids called 'sake cake'

This process uses 120-150 bags,and removing the sale from then is difficult. (Our sake cake are delicious because of traditional press machine.)

8,Bottling and storage

Once sake bottled the process is basically complete.

Once sake bottled the process is basically complete.

Sake bottled are heated to 60-65C to kill any bacteria and preserve the quality of sake.